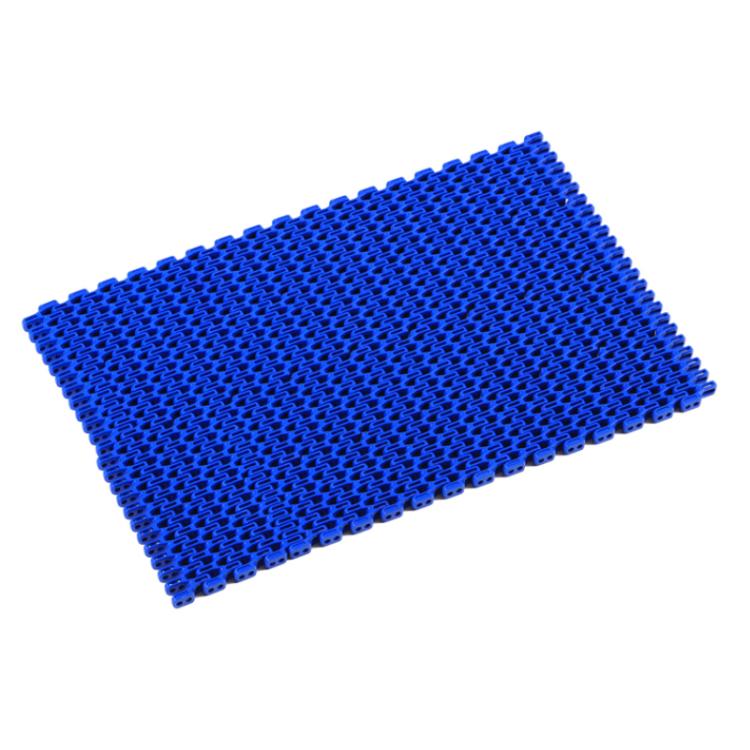

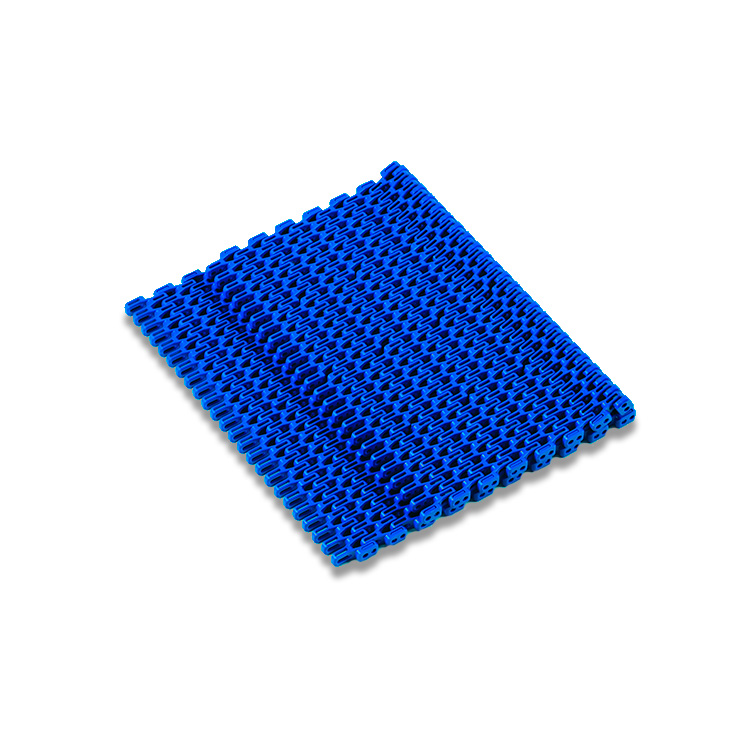

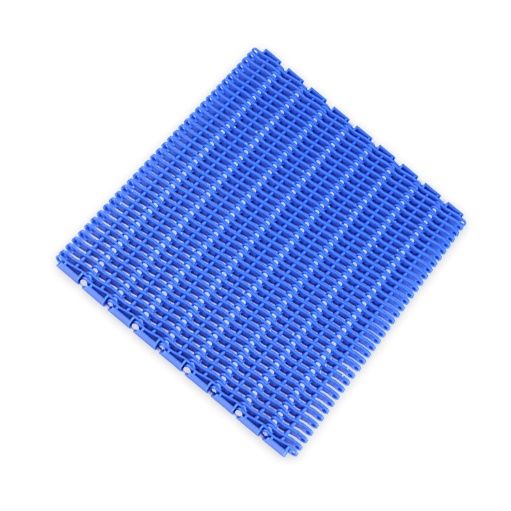

7100 flush grid turnable plastic modular conveyor belt

Video

Product Parameters

| Modular Type | 7100 | |

| Standard Width(mm) | 76.2 152.4 304.8 457.2 609.6 762 914.4 1066.8 152.4N | (N,n will increase as integer multiplication; due to different material shrinkage,Actual will be lower than standard width) |

| Non-standard Width(mm) | 152.4+12.7*n | |

| Pitch | 25.4 | |

| Belt Material | POM | |

| Pin Material | POM/PP/PA6 | |

| Work Load | Straight:30000; In Curve:600 | |

| Temperature | POM:-30C°~ 80C° PP:+1°~90C° | |

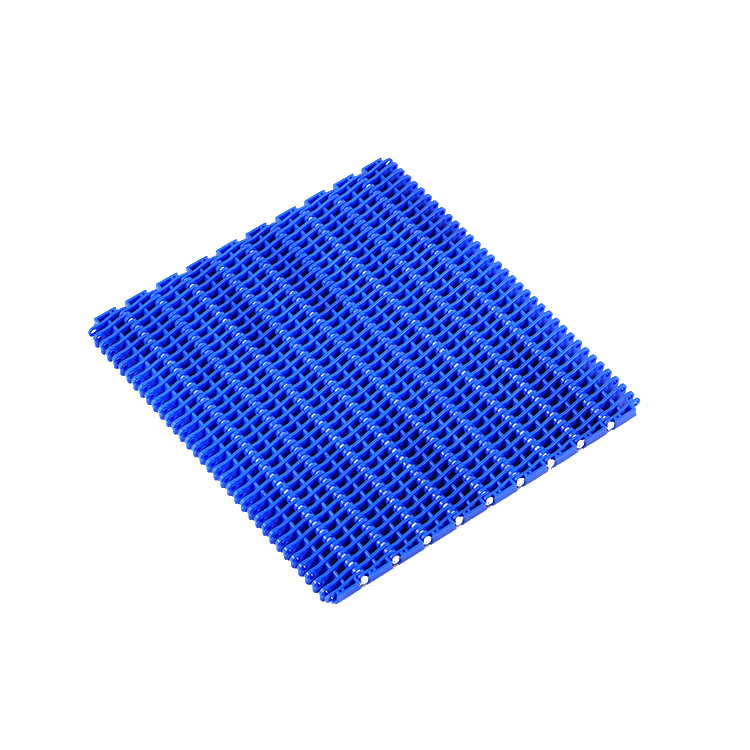

| Open Area | 55% | |

| Radius(Min) | 2.3*Belt Width | |

| Reverse Radius(mm) | 25 | |

| Belt Weight(kg/㎡) | 7 | |

7100 Machined Sprockets

| Machined Sprockets | Teeth | Pitch Diametet(mm) | Outside Diameter | Bore Size | Other Type | ||

| mm | Inch | mm | Inch | mm | Available on requestBy Machined | ||

| 1-S2542-20T | 9 | 74.3 | 2.92 | 73.8 | 2.90 | 20 25 35 | |

| 1-S2542-20T | 10 | 82.2 | 3.23 | 82.2 | 3.23 | 20 25 35 40 | |

| 1-S2542-25T | 12 | 98.2 | 3.86 | 98.8 | 3.88 | 25 30 35 40 | |

| 1-S2542-25T | 15 | 122.2 | 4.81 | 123.5 | 4.86 | 25 30 35 40 | |

Application Industries

Food Industry:

Snack Food(tortilla chips ,pretzels, potato chips,) ;Poultry,Seafood,

Meat (beef & pork) ,Bakery,Fruit & vegetables

Non-food Industry:

Packaging,Printing/Paper,Can manufacturing,Automotive,Tire manufacturing,Postal, Corrugated cardboard, Etc.

Advantage

a.Heavy load capability

b.Long service life

c.Meet the requirements of food production

Features and characteristics

7100 plastic conveyor belt, also call plastic steel belt, It is mainly used in plastic steel belt conveyor and it is a supplement to the traditional belt conveyor, it overcomes the belt machine belt tear, puncture, corrosion shortcomings, to provide customers with a safe, fast, simple maintenance of transportation. Due to it’s modular plastic belt and the transmission mode is sprocket drive,So it is not easy to crawling and running deviation, the modular plastic belt can withstand cutting, collision, and oil resistance, water resistance and other properties, therefore it will reduce the maintenance problems and related cost.

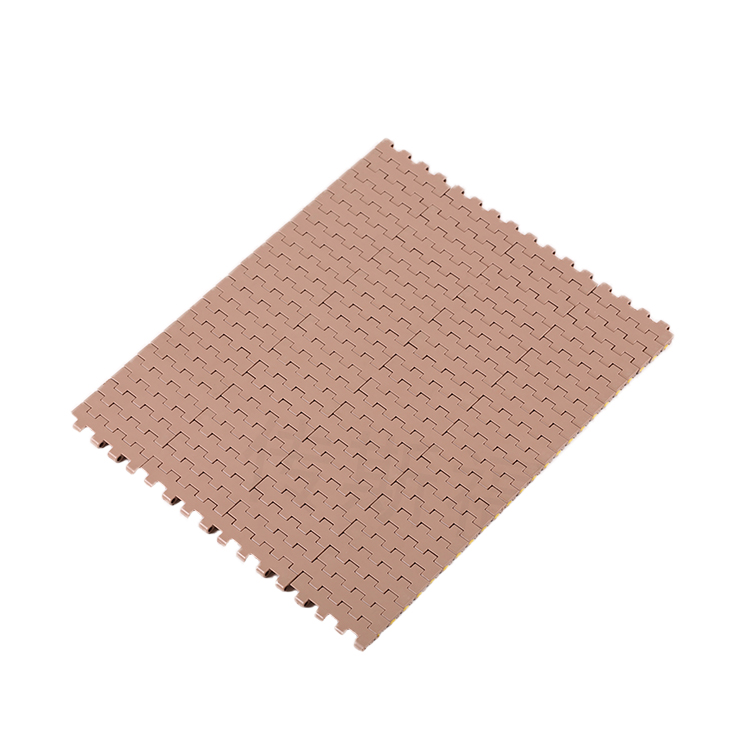

Different materials can play a different role in conveying and meet the needs of different environments. Through the modification of plastic materials, the conveyor belt can meet the conveying requirements of the environmental temperature between -10 degrees and 120 degrees Celsius. belt pitch 10.2, 12.7, 19.05, 25, 25.4, 27.2, 38.1, 50.8, 57.15 optional, opening rate from 2% to 48% optional, according to the trepanning status it can classify flush grid belt ,flat top belt ,trepanning belt ,Round hole belt,rib betl.

Physical and chemical properties

Acid and alkali resistance (PP) :

7100 modular plastic flush grid turnable conveyor belt using pp material in acidic and alkaline environment has better transport capacity

Antistatic

Resistance value less than 10E11Ω products for antistatic products better antistatic product resistance value of 10E6Ω to 10E9Ω due to low resistance value, antistatic products have conductive function, can discharge static electricity. A product with a resistance greater than 10E12 ohms is an insulated product, which is prone to generate static electricity and cannot be discharged.

Wear resistance

Wear resistance refers to the ability of a material to resist mechanical wear. Attrition per unit area per unit time at a certain wear rate under a certain load.

Corrosion resistance

The ability of a metal material to resist the corrosive and destructive action of the surrounding medium is called corrosion resistance.