How to Optimize Your Assembly Line with Modular Conveyor Parts

Table of Contents

- Benefits of Modular Conveyor Systems in Assembly Lines

- Key Considerations for Selecting Modular Conveyor Parts

- Step-by-Step Guide to Integrating Modular Conveyors into Your Workflow

- Top Brands Offering High-Quality Modular Conveyor Solutions

- Common Mistakes to Avoid When Implementing Modular Conveyors

- Future Trends in Modular Conveyor Technology for Assembly Lines

- FAQS

- Conclusion

- Related Posts

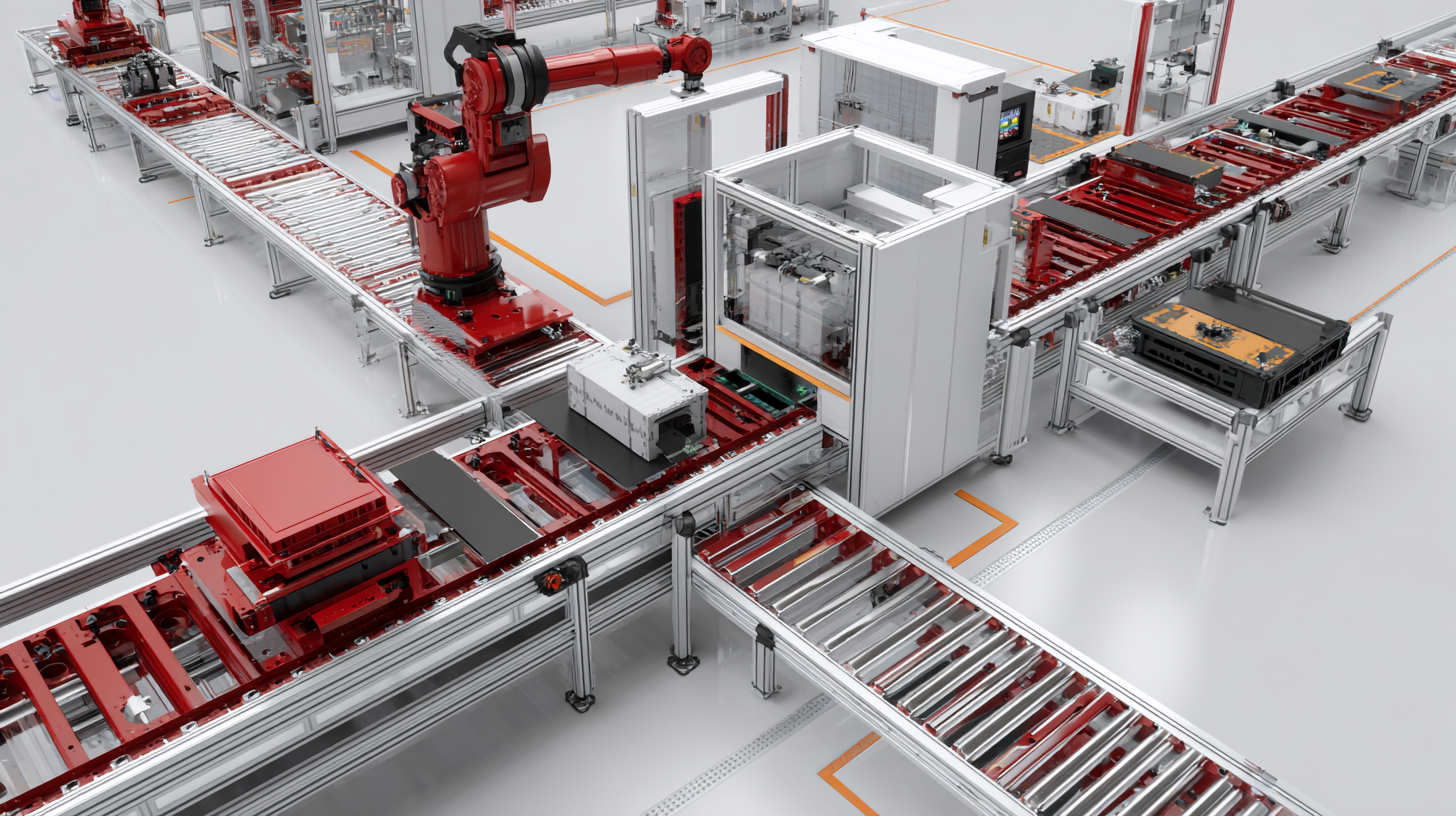

In today's competitive manufacturing landscape, optimizing assembly lines has become crucial for enhancing efficiency and productivity. According to a recent industry report, nearly 70% of manufacturers are leveraging modular conveyor systems to streamline their operations. Modular Conveyor Parts offer unparalleled flexibility, allowing businesses to easily customize their assembly lines to meet evolving production demands.

Changshuo Conveyor Equipment (Wuxi) Co., Ltd. is at the forefront of this innovation, specializing in a wide range of conveyor solutions, including belt conveyors, flexible chain conveyors, and modular belts. By integrating Modular Conveyor Parts into their systems, manufacturers can reduce downtime, improve throughput, and adapt to changing workflows, ensuring they remain competitive in an ever-evolving market.

Benefits of Modular Conveyor Systems in Assembly Lines

Modular conveyor systems are transforming the efficiency and adaptability of assembly lines across various industries. These systems allow manufacturers to customize their assembly processes according to specific production requirements, facilitating smooth transitions between different products. With the rise of high product variability, businesses are increasingly adopting modular solutions to enhance workflow. For instance, a recent installation by a graphics manufacturer demonstrates how an overhead conveyor system streamlines operations while supporting diverse product lines.

The benefits of modular conveyor systems extend beyond just flexibility; they also promote intelligent automation. Recent advancements have shown that integrating intelligent conveyors can significantly boost production output while reducing costs. Companies can create virtual twins of their production lines, enabling them to optimize layout and efficiency before actual implementation. This approach not only minimizes commissioning time by up to 70% but also leads to sustainable operations, as seen in the introduction of energy-efficient and recyclable conveyor systems. As industries continue to evolve, modular conveyor systems stand out as a viable solution to meet the growing demands of modern manufacturing.

Key Considerations for Selecting Modular Conveyor Parts

When selecting modular conveyor parts for your assembly line, it's crucial to consider factors that significantly impact performance and efficiency. Understanding the specific requirements of your industry—such as food safety in the food and beverage sector or adaptability for dairy processing—can guide you in making informed choices. For instance, dairy processors must recognize that "one size does not fit all," ensuring their conveyor systems are tailored to optimize plant efficiencies and maintain high standards of food safety.

Tips for Choosing Modular Conveyor Parts:

- Assess the Material Flow: Evaluate the types of materials being transported and determine the conveyor paths. The right modular parts can easily accommodate diverse products and configurations.

- Maintenance and Cleaning: Regular maintenance is key in the food industry; consider modular parts that allow for easy cleaning and part replacement. Systems designed for quick access can enhance hygiene and operational uptime.

- Embrace Technological Advancements: Leverage innovations such as machine vision technology to optimize bin picking processes and enhance conveyor efficiency. The integration of smart systems can significantly decrease manual handling and improve accuracy.

By focusing on these key considerations when selecting modular conveyor parts, your assembly line can achieve increased productivity and reliability, ultimately leading to greater operational success.

Step-by-Step Guide to Integrating Modular Conveyors into Your Workflow

Integrating modular conveyors into your workflow can significantly enhance the efficiency of your assembly line. This step-by-step guide focuses on how to successfully adopt these systems to streamline operations. Begin by assessing your current workflow and identifying areas where bottlenecks occur. Modular conveyors can be tailored to address specific challenges, providing flexibility in design and ease of integration.

Once you’ve outlined the workflow requirements, it’s essential to select the right modular conveyor components that suit your needs. This selection process should emphasize compatibility with existing equipment and the scalability required for future expansions. For instance, a modular design allows for easy upgrades and adjustments, similar to the digitisation workflow that emphasizes quality and modularity.

Finally, implement the modular components incrementally to monitor performance and make necessary adjustments. This phased approach not only minimizes disruptions but also enables you to assess the improvements in efficiency step by step. In doing so, you not only optimize your assembly line but also create a robust infrastructure that can adapt to changing demands.

Top Brands Offering High-Quality Modular Conveyor Solutions

When it comes to optimizing your assembly line, selecting the right modular conveyor parts is crucial. Numerous brands in the market offer high-quality modular conveyor solutions that can significantly enhance operational efficiency. Companies specializing in modular conveyor systems provide versatile design options that cater to various production needs. Whether you require belt conveyors, flexible chain systems, or roller conveyors, the right choice can streamline your processes and reduce downtime.

Tips for selecting the best modular conveyor parts include assessing your specific workflow requirements and evaluating the adaptability of the conveyor systems. Look for components that can be easily integrated and reconfigured as your production demands change. Also, consider the durability and maintenance needs of the conveyors to ensure longevity and reliability in your operations.

Another consideration is the availability of conveyor components that work seamlessly together, facilitating a smoother assembly line experience. Opt for suppliers that offer comprehensive support and a wide range of options, from plastic chain plates to modular belts. This minimizes compatibility issues and allows for quick replacements or upgrades when necessary.

How to Optimize Your Assembly Line with Modular Conveyor Parts

| Feature | Description | Benefits | Cost Efficiency |

|---|---|---|---|

| Modular Design | Easily configurable to fit different layouts. | Increased flexibility for production needs. | Reduces labor costs due to simpler installations. |

| Durable Materials | Constructed from high-quality, lasting materials. | Less frequent replacements needed, saving costs. | Lower maintenance expenses over time. |

| Easy Maintenance | Designed for quick access and simple repairs. | Minimized downtime and enhanced productivity. | Reduces costs associated with long downtimes. |

| Scalability | Can be expanded as business grows. | Facilitates growth without major investments. | Saves on future expansion costs. |

| Customizable Modules | Allows specific configurations for unique needs. | Meets specific production requirements effectively. | Reduces waste from unused features. |

Common Mistakes to Avoid When Implementing Modular Conveyors

Implementing modular conveyors in your assembly line can greatly enhance efficiency and flexibility, but it’s essential to avoid common pitfalls that can derail your operations. One frequent mistake businesses make is underestimating the importance of thorough planning. According to a recent industry report, improper layout design can lead to a 25% decrease in productivity. Take the time to analyze your workflow and determine the optimal arrangement for your modular conveyor parts to ensure smooth operation.

Another common mistake is neglecting proper training for staff on new modular systems. A study by the Conveyor Equipment Manufacturers Association (CEMA) highlights that companies investing in employee training have seen productivity increases of up to 40%. Ensure that your team is well-equipped to handle the transition to modular conveyors, focusing on maintenance and operation procedures.

**Tip:** When selecting modular components, consider compatibility with existing systems to prevent integration issues.

Additionally, keep a close eye on the quality of the parts used in your conveyor systems. Cheap components can lead to higher failure rates and increased downtime, which can be detrimental in a fast-paced production environment. Rely on trusted manufacturers like Changshuo Conveyor Equipment (Wuxi) Co., Ltd., known for their high-quality products, to enhance your assembly line reliability.

Optimization of Assembly Line Efficiency Using Modular Conveyors

Future Trends in Modular Conveyor Technology for Assembly Lines

As manufacturing processes evolve, modular conveyor technology is poised to play a pivotal role in the future of assembly lines. One of the key trends is the increasing integration of smart technologies, such as IoT sensors and AI analytics, which enable real-time monitoring and predictive maintenance. This technological synergy not only enhances efficiency but also reduces downtime. By providing immediate data feedback, manufacturers can optimize their assembly line operations, swiftly identify bottlenecks, and adapt processes as needed.

As manufacturing processes evolve, modular conveyor technology is poised to play a pivotal role in the future of assembly lines. One of the key trends is the increasing integration of smart technologies, such as IoT sensors and AI analytics, which enable real-time monitoring and predictive maintenance. This technological synergy not only enhances efficiency but also reduces downtime. By providing immediate data feedback, manufacturers can optimize their assembly line operations, swiftly identify bottlenecks, and adapt processes as needed.

Another emerging trend is the emphasis on sustainability and flexibility in modular conveyor systems. Manufacturers are now seeking eco-friendly materials and energy-efficient designs that minimize waste and reduce their carbon footprint. Furthermore, the modular nature of these systems allows for rapid reconfiguration, accommodating diverse production needs without significant downtime. This versatility is crucial in today’s dynamic market where customization and quick adaptation to consumer demands are essential for staying competitive. As these trends continue to shape the industry, businesses that leverage modular conveyor technology will be well-positioned for success in a rapidly changing landscape.

FAQS

: Modular conveyors are flexible conveyor systems that can be customized to fit specific workflow needs. They enhance efficiency by enabling streamlined operations and addressing bottlenecks within the assembly line.

The first step is to assess your current workflow and identify areas where bottlenecks are occurring. This analysis will help determine how modular conveyors can be tailored to your specific challenges.

When selecting components, focus on compatibility with your existing equipment and the scalability for future expansions. Ensure that the modular design allows for easy upgrades and adjustments as needed.

It is advisable to implement the modular components incrementally. This phased approach allows for monitoring performance and making adjustments to minimize disruptions while improving efficiency.

Common mistakes include underestimating the importance of planning the layout, neglecting proper training for staff, using low-quality components, and failing to ensure compatibility with existing systems.

Thorough planning is crucial as improper layout design can lead to significant decreases in productivity, potentially by as much as 25%. A well-analyzed workflow results in the optimal arrangement of conveyor parts for smooth operation.

Staff training is highly important; companies that invest in training see productivity increases of up to 40%. Training should focus on maintenance and operation procedures to ensure a smooth transition.

Always prioritize quality when selecting conveyor components. Using cheaper parts can result in higher failure rates and increased downtime, negatively affecting production efficiency.

Yes, modular conveyor systems are designed to be adaptable and can be easily adjusted or upgraded to meet changing production demands.

Changshuo Conveyor Equipment (Wuxi) Co., Ltd. is mentioned as a reliable manufacturer known for producing high-quality modular conveyor components that enhance assembly line reliability.

Conclusion

In modern assembly lines, the integration of Modular Conveyor Parts offers significant advantages, enhancing efficiency and flexibility. These systems allow for tailored solutions that can adapt to various workflows, making them an essential asset for manufacturing operations. When selecting modular conveyor parts, it’s vital to consider factors such as compatibility, scalability, and the specific needs of your production line.

Implementing these systems requires a carefully crafted approach, beginning with a detailed analysis of your workflow. By avoiding common pitfalls and focusing on quality options from trusted brands, you can ensure a successful integration. Looking ahead, advancements in modular conveyor technology promise even greater enhancements in automation and efficiency, positioning companies like Changshuo Conveyor Equipment (Wuxi) Co., Ltd. at the forefront of these innovative solutions.

Related Posts

-

Conveyor Belt Parts Local Solutions Driving Global Success

-

Essential Checklist for Selecting the Best Modular Conveyor System for Your Business Needs

-

Navigating the Future of Modular Plastic Belt Conveyors in 2025 Technology Advancements Guide

-

How to Choose the Right Packaging Conveyor Belt for Your Production Line Needs

-

How to Optimize Your Conveyor Belt System for Maximum Efficiency

-

7 Compelling Advantages of Using Modular Plastic Conveyor Belts in Your Operations

Blog Tags:

Landon

-

-

-

-

-

Top